Concept

Up to now the supervision of mechanical safe deposit systems has only been viable with great expenditure.

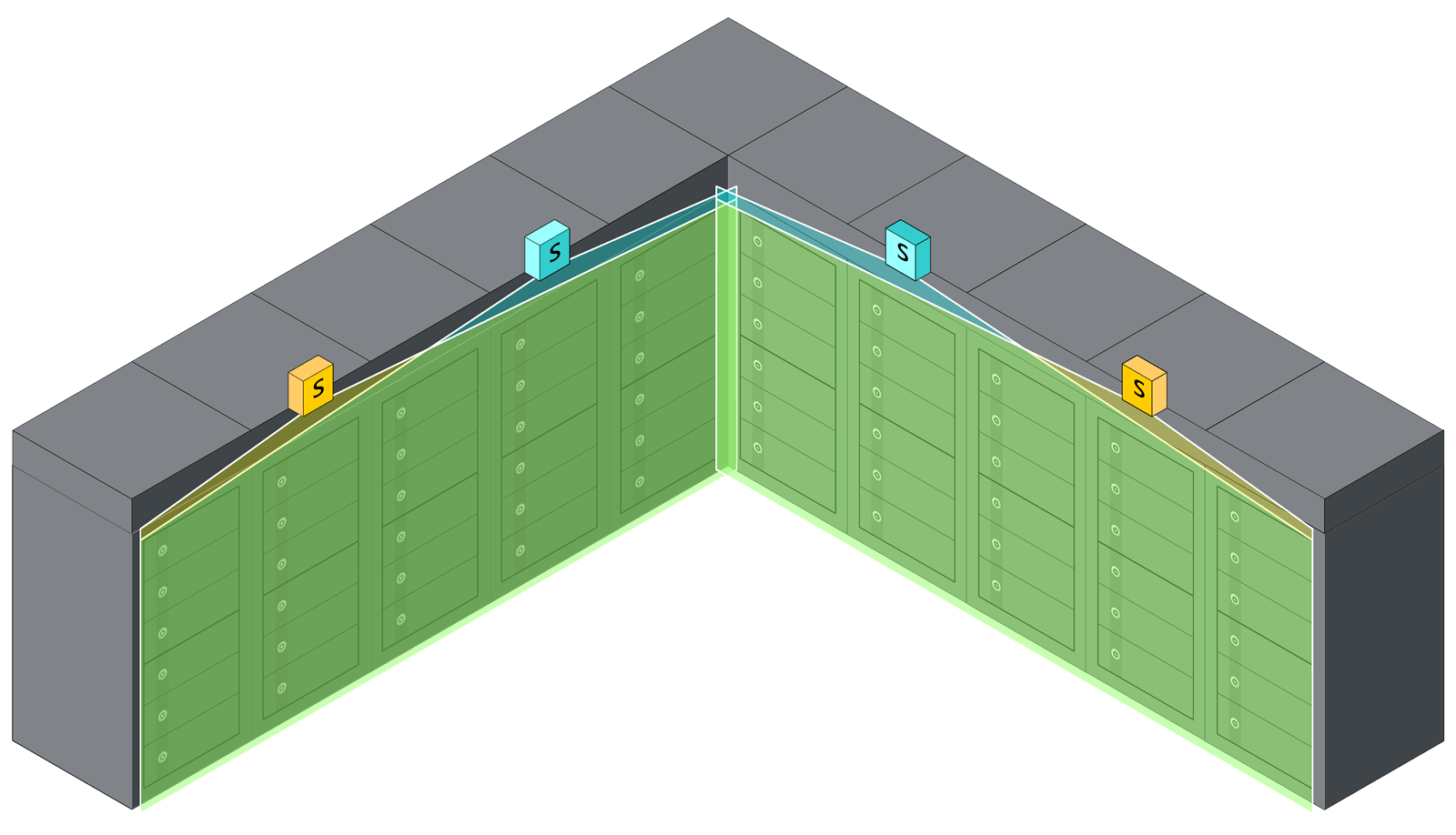

Through subtle use of industrial lasers we have worked out a system for auditing acceptable supervision of mechanical safe deposit systems that can be easily mounted as well as integrated optically inconspicuous. In doing so the lasers work reliably and nearly maintenance free.